Electric forklifts are most popularly used for indoor warehousing applications. With reduced fuel cost and high efficiency, electric forklifts & electric stackers become an optimum choice for a warehouse. Let’s take a look at the details that make electric forklifts the ideal choice for your warehouse.

Here are 4 benefits of using an electric forklift.

1. Less Noisy

In a bustling warehouse, it is easy to undervalue the importance of a noise-free environment until you experience the impact it can have on your productivity. This is true especially for smaller spaces with multiple forklifts traveling around collectively creating an amplified noise. The electric forklift engines are relatively noise-free as compared to diesel-powered engines. This can be a huge plus point for workers as they can easily communicate with each other without yelling. This also avoids damage to the earpads of the operators and helps keep their minds calm & the overall ambiance peaceful.

2. Pollution Free

The problem of emission is common with LPG gas or diesel operated engines. Electric forklifts do not emit any CO2 gases. They have zero emissions. This helps curb the issue of pollution thus maintaining the surrounding environment and employee health.

3. Reduced Heat Dissipation

IC forklifts produce significant heat from their fuel combustion, which dissipates and spreads into the warehouse space or presents hot surfaces on exhaust pipes that can burn or scald a worker. While electric forklifts consume only the energy they require without inefficiently wasting fuel while idling or while pouring out the pipe.

4. Lesser Overall Costing

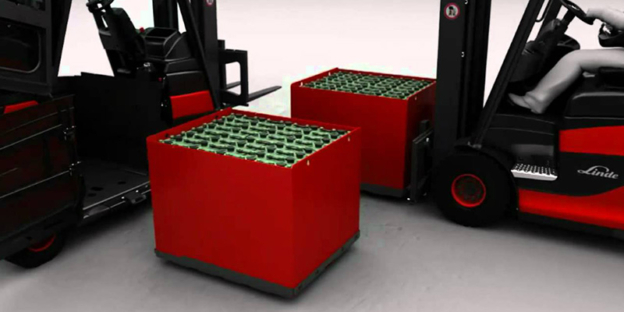

The operating cost of electric forklifts calculates to be lower than the IC models. The equipment is also better priced, for instance, the electric stacker price with Linde is best in industry. Since IC models run on fuel and electric ones on the charge, you have the one-time investment of setting up a charging station at your warehouse. However, the maintenance cost is lower than fuel based engines.

5. Comes In Many Varieties

There are so many options available in electric forklifts from electric tow trucks & electric stacker to

battery operated pallet truck & very narrow aisle truck. Be it maneuvering your way through those narrow lanes or stacking boxes at greater heights or lifting heavy weights for shorter distances, you can choose according to your warehouse requirements. Linde MHE has an electric truck for all your needs.

Considering all the above points, Electric forklifts scores better in terms of investment and usage. If you are looking for your options on industrial forklifts, visit Linde MHE.